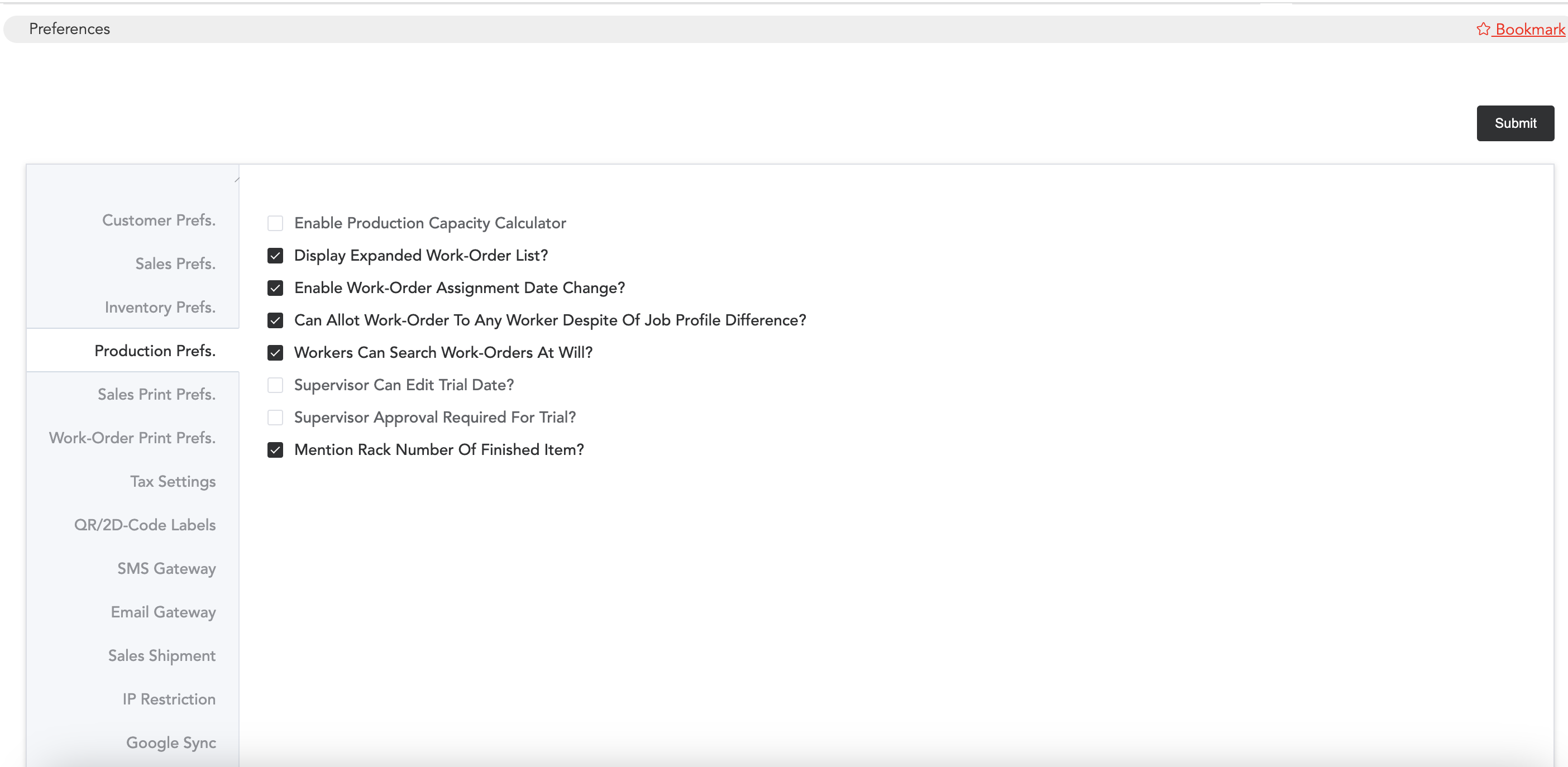

Production Prefs.

The production settings will help you manage and apply different restrictions on the production, worker and work orders as per the use case.

Go to Setup then Preferences and then Production Prefs.

Enable Production Capacity Calculator, this will calculate the delivery date as per the production capacity.

By enabling ‘Display Expanded Work-Order List’ the work-order list will be displayed in a detailed way, which will show the current location, shop name, and the fabric code in individual columns in all work order window.

‘Enable Work-Order Assignment Date Change’ is if you enable this, date change can be done in the production history of the work-order window, that is you can change when the work started and when finished.

‘Can Allot Work-Order To Any Worker Despite of Job Profile Difference’, enable this only if you want all worker’s names to appear while assigning production processes to them. Otherwise, only the particular worker’s name to whom that particular production process is allotted, will appear while assigning production processes.

‘Workers Can Search Work-Orders At Will’, you may enable this if you want your production workers to search any work orders, and mark the work start when they start the work and then mark finish when the work is finished.

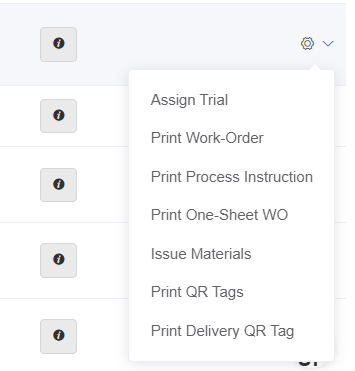

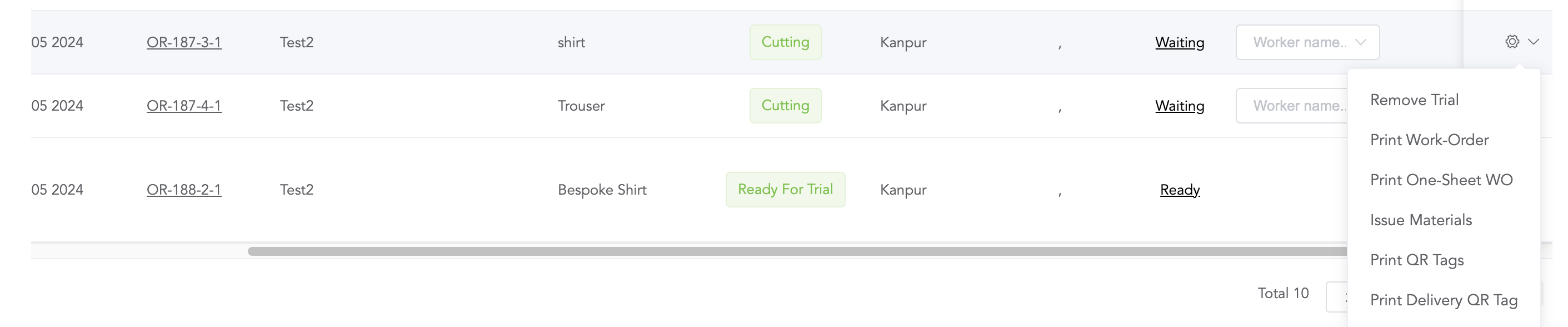

If you select/enable Supervisor Can Edit Trial Date then the production supervisor can assign trial. If it is enabled, the Assign Trial option will appear in all work order window. From there the supervisor can click on assign trial and select the trial type, The trial can be done and updated from the trial window.

Also, if the trial has been assigned previously, the supervisor can have the right to remove it.

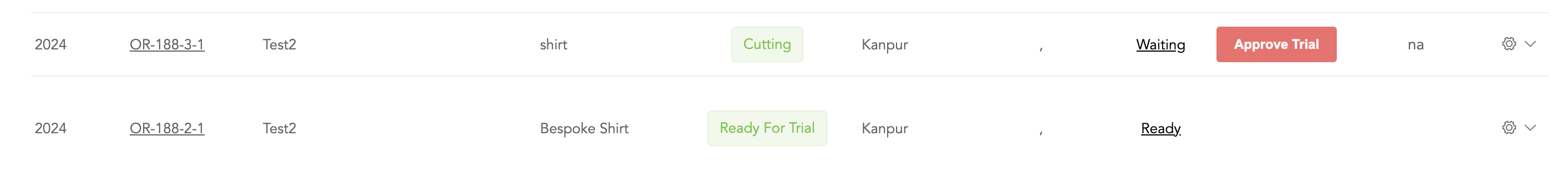

Selecting/enabling the option Supervisor Approval Required For Trial will provide an approval option before the trial process starts. The supervisor can approve and then assign workers for the trial process.

If you enable the option Mention Rack Number Of Finished Item, then when a production process is finished, it will ask for the rack number, in which you kept the item. Once you enter the number it will move on to the next process.

Submit it after making any changes.